Michael Good

Digital Equipment Corporation

Nashua, New Hampshire 03062 USA

Originally published in Proceedings of CHI ’92 Human Factors in Computing Systems (Monterey, CA, May 3-7, 1992), pp. 439-446. Included here with permission. Copyright © 1992 by ACM, Inc.

Abstract

Customer-driven design processes such as participatory design can be used to develop new presence, or virtual reality, technology. Chemists worked together with computer company engineers to develop scenarios for how presence technology could be used to support future molecular modeling work in drug design. These scenarios led to the development of a portable torque-feedback device which can he used with either workstation or virtual reality technology. This paper discusses both the experience with the participatory design process and the novel features of the portable torque-feedback device.

Keywords: Presence, virtual reality, participatory design, force feedback, molecular modeling, chemistry.

Introduction

Whether it is called virtual reality, artificial reality, cyberspace, or presence, the technology that enables participants to see, hear, feel, and walk around a computer-generated world has captured the public imagination. Accompanying this enthusiasm are serious questions about the usefulness of presence technology. One belief is that “Artificial reality will just be a gadget for rich countries,” affecting only military and Nintendo game applications [3].

How might we take presence technology beyond gadgetry and make it useful for diverse people doing different types of work? My approach has been to apply the techniques of participatory design [1, 9] to the development of presence technology. In Digital’s Presence project, chemists collaborated with computer engineers to develop new prototypes of presence technology. As Laurel [11] suggests, our starting point is to design the experience that we want people to have when using computers in their work.

In this paper, I will first set the context by briefly describing the portion of the chemists’ drug design work on which we focused, and then describing the technological background in presence that the computer engineers brought to the project. I will then discuss our experience with the participatory design process, and how it led to the development of a new force-feedback device, the portable torque-feedback device (patent pending).

Context

Participatory design is a collaborative process. Computer users are the experts in their work, while computer designers are the experts in computer technology. Participatory design brings these two backgrounds together to create new systems with the goal of improving the quality of work life, as shown in Figure 1.

Figure 1: Dynamic Interaction Between Technology and Work

Figure 1: Dynamic Interaction Between Technology and Work

Blomberg and Henderson [1] describe three basic aspects of participatory design: the goal of improving the quality of work life, a collaborative orientation, and an iterative process. An important part of participatory design is what Ehn [4] calls the balance between tradition and transcendence. In participatory design, new technology explicitly incorporates the history of how work has been done in the past while simultaneously improving how work can he done in the future.

Molecular Modeling

Our customers were members of a molecular modeling group at a pharmaceutical company, working in the drug discovery process. The discovery and development of new drugs is a long, complex process. We focused on one piece of the discovery process for one category of drugs called enzyme inhibitors.

Enzyme inhibitors are small molecules that can dock, or bond, with larger enzyme molecules at an active site. By docking at the active site, the small molecules inhibit or stop an undesired chemical reaction produced by the enzyme. Stopping the chemical reaction can serve to relieve undesired symptoms. The inhibitor might be made up of about sixty atoms while the enzyme itself is made up of thousands of atoms.

One of the many problems in enzyme docking is that neither the enzyme inhibitor nor the enzyme is rigid. Both can twist into many different layouts, called conformations. Exploring these different layouts is called exploring the conformational space of the molecules. One common goal is to look for conformations with low energy for both the enzyme inhibitor and the enzyme, since this tends to make docking easier.

Exploring conformational space is one of many applications of molecular modeling. Chemists have many molecular modeling tools available. Perhaps the most popular tools are physical models, such as Dreiding stick models. These physical models are similar to the ball-and-stick models used in chemistry classes, but adapted for professional use. Many computerized molecular modeling systems are also available [e.g. 13].

While the computerized systems are becoming more frequently used, they are resisted by many chemists. Cost is a major issue, but there are usability issues as well. Even a system that appears well-designed and based on established graphical user interface principles can distance a chemist from a physical understanding of the nature of the enzyme and the candidate enzyme inhibitor molecules.

The chemists’ goal for the project was to find new technologies that could he used as the basis for new molecular modeling tools for enzyme docking. These tools would combine the benefits and usability of existing physical and computerized modeling tools.

Presence

The computer engineers brought a particular technical focus to participatory design. This technical focus was to increase the quality of presence for computer users.

Presence has several characteristics. Presence is related to a feeling of computer transparency, where the interface to a computer fades into the background [7]. As presence or transparency increases, so does the experience of working on a task as opposed to working on a computer. This has long been a goal in developing usable systems.

From a design perspective, presence expresses the qualities of a product that can he perceived by one or more of our senses [5]. Research in multisensory human-computer interaction currently focuses on making greater use of the senses of vision, touch, and hearing.

From a perspective in rhetoric and argumentation, presence is the quality which makes certain elements important and pertinent to an audience [15]. One historical method to increase presence is to use concrete rather than abstract objects.

Our use of the term “presence” refers to the quality of human-computer interaction that makes systems more transparent to the user, makes greater use of the senses, and makes the abstract concrete. Presence is not a distinct category of computer technology like menu systems, direct manipulation, or virtual reality [18]. Many different technologies can he used to achieve greater presence through computers, depending on the nature of the work and on individual and group preferences.

Our technological focus started with virtual reality technology [16]. Our participatory design experience expanded that focus to include workstation technology enhanced with multisensory l/O devices. Artificial reality [10] is another technology for achieving presence in some contexts. We did not include it in our technological focus due in part to the lack of tools for developing working prototypes.

The computer engineers’ goal for the project was to develop new presence technology that could improve work life for our customers in the future by providing more transparent, sensory, and concrete systems. Molecular modeling has already been a driving problem behind the multisensory research at the University of North Carolina [2]. We expected that working with chemists would he especially useful for developing new ways to support the sense of touch in the use of computers.

Participatory Design Experience

Participatory design offers rich methodological possibilities for building powerful computer application systems. This project applied participatory design methodology to a somewhat different area: the development of presence technology. The computer engineers worked in the context of product development organizations that have traditionally built general-purpose systems for diverse customers.

My initial conception of the participatory design process was to view it in five steps:

- Building relationships. We would spend enough time to ensure a good fit between customer-participants and the Presence project. This included familiarizing our customers with presence technology.

- Contextual inquiry. Contextual inquiry emphasizes interview methods conducted in the context of the participant’s work and building an understanding of work in context [19]. The computer engineers needed to build an understanding of the customer’s work before we could collaborate as co-designers.

- Brainstorming. Brainstorming sessions, where all ideas are recorded and criticism of ideas is forbidden, would generate many ideas for how presence technology could improve work life.

- Storyboarding. Customers and computer engineers would develop some of the most promising brainstorming ideas into illustrated scripts of a “day in the life” of a customer using presence technology in the future [14].

- Iterative design. Using the storyboards as specifications, the computer engineers would build prototypes that would be tested by the customer-participants on a regular basis. All the previous steps would continue in an iterative fashion.

Our participatory design work with chemists was one of three simultaneous participatory design projects for developing presence technology. In the other projects, where the computer users were toy designers and computer industrial designers, we followed this 5-step process. After spending several months in building relationships, the initial design visits lasted 2 days. The first day was spent in contextual inquiry, and the second day was divided between brainstorming and storyboarding. Subsequent iterative design sessions lasted 1 day.

With the chemists, however, the initial design session was less structured. Contextual inquiry and storyboarding activities flowed together, and brainstorming activity was generally absent. Storyboarding did not produce a full illustrated script, but rather a scenario for use of new technology. We adapted the design techniques on the fly in response to the work context. Participatory design is a collaborative approach to design, not a rigid set of design methods.

In the rest of this section I will describe our experience in working with the chemists in building relationships, contextual inquiry, and storyboarding. The next section will then describe our progress in moving from the scenario to the prototype tested in our first iterative design session.

Building Relationships

Conducting participatory design in a large product development organization presents many challenges. Grudin [6] identifies many of these challenges and their various sources in the nature of product development, in the division of labor within product development organizations, and in the use of standard software development procedures and techniques. Two of these challenges took months for us to overcome: identifying appropriate customer participants, and then obtaining access to the participants.

I tried several approaches in order to find appropriate customer participants for this project. One approach that did not work was simply to call or send electronic mail to the sales representative in charge of a promising account. A much more successful technique was to discuss this project in Digital’s VAX Notes conferences, which serve as electronic bulletin boards for a variety of technical and employee interests. Interested sales representatives then contacted me in response to these notes. These contacts could take days or months to develop. Two months elapsed from the time I placed a note in the pharmaceutical industry conference before a sales representative contacted me about the project.

Initial contacts enabled the customers and me to build a working relationship before beginning the actual design sessions. The pharmaceutical customers had already planned a visit to Digital to hear about future technologies in other areas, so my presentation was included in that visit. This meeting took place 2 months after the initial contact with the Digital sales representative. Two months later we arranged the first design meeting.

Overall, 5 months elapsed between the first contact with the sales representative for the pharmaceutical company and the first on-site participatory design visit. It took only half that time to then develop the torque-feedback device and presence software prototypes for molecular modeling and have them ready for the first iterative design session.

Part of the reason that the process took so long is systemic, as Grudin discusses, but part is particular to the nature of this project. We needed to find customer groups who were already familiar with state-of-the-art computer systems for their applications and whose mission included looking for new technology which could help solve their difficult problems. These groups also needed to include intended users of the new technology: chemists who were familiar with computers, not just computer people who were familiar with chemistry. Research and development groups made the best candidates for this work.

Contextual Inquiry

We use contextual inquiry to understand the nature of the user’s work, how computers are involved in that work, and how the use of computers supports and disrupts the work process. Interviewing customers as they use a computer system is particularly effective for understanding the ongoing usage of a computer system, rather than the summary experience that customers recollect alter the fact. Such interviews are often hit-or-miss regarding job content, though, and are not usually sufficient by themselves to get an overall understanding of the work process.

One technique we use to provide more context is to have customers give us an overview of their entire work process, using artifacts of that process wherever possible. An overview of the entire drug design process would have been too complex for the computer designers to follow. Instead, our customers focused on the portion of drug design that they viewed as most relevant: the creation of drugs from enzyme inhibitors. After reviewing the basic chemistry, the molecular modelers demonstrated some current modeling techniques with both physical models and computer models. All the computer engineers had extensive collegiate math and science backgrounds, which helped in understanding the chemists’ work.

One chemist’s work was particularly inspiring for future designs. He had found the current computerized representation of the enzyme active site too limiting, even with the use of stereoscopic displays and fast 3-D rendering systems. He constructed an elaborate foam-core physical model of the enzyme active site, with the cavity of the model representing the conformation of the enzyme that was of the greatest interest. After constructing this model he was very excited, so he rushed to get his Dreiding model of the enzyme inhibitor and physically experiment with moving the Dreiding model of the enzyme inhibitor around the foam core model of the enzyme active site. But this did not work either: the problem was simply too complex for either the physical model or the computer model to be fully understandable on their own. The chemist wound up going back and forth between the physical model and the computer model to figure out the proper conformation of the enzyme inhibitor which would lead to a good dock.

This and similar sessions led to the idea of combining the advantages of computer models and physical models. Physical models in many ways provide greater presence for the chemists and are closer to the traditional work practice. Computerized models offer many ways to transcend the current work practice, including the ability to get quantitative results. Why not combine the two into an electronic Dreiding model, where the computer model can be manipulated physically, like existing Dreiding models?

A key element of contextual inquiry involved having the computer engineers tour the work facilities. Most of our participatory design work at the pharmaceutical company took place in conference rooms, but we did tour the molecular modeling laboratory and individual offices, as well as getting a walking tour of the entire complex. Absorbing the physical feeling of the workplace helped the computer engineers better understand the context of the customers’ work.

After doing some storyboarding around the electronic Dreiding model ideas, we returned for further contextual inquiry sessions. Another chemist demonstrated the use of the group’s existing molecular modeling software package in more detail. This demonstration then fed into further storyboarding work.

Storyboarding

“Day in the life” scenarios and storyboards both can serve as specifications for prototypes. Both techniques emphasize narrative, rather than theory, as the primary source for design [17]. Scenarios describe situations where customers would use new technology in the future. Storyboarding goes to an additional level of detail by creating an illustrated script for this scenario. Storyboarding thus can provide a more detailed specification for prototype software. In this case, our scenario was simple enough that the lack of an illustrated storyboard did not hamper our later prototyping work.

The molecular modelers developed a scenario based on an electronic version of the mechanical stick models that chemists already use. The electronic model could be physically manipulated like the mechanical models while supporting several new capabilities, such as ease of filing and providing quantitative energy calculations. Physical manipulation keeps the kinesthetic presence that is missing in current molecular modeling software. Quantitative results such as energy calculation and minimization provide important and pertinent information that is not present for chemists when using the mechanical models.

This scenario illustrates the balance between traditional work practice and the new possibilities offered by presence technology. It based on the existing work practice of the Dreiding models, but adds numerous capabilities that are not provided by those models. The visual representation of the electronic Dreiding model would follow the practice of the chemists’ existing molecular modeling software.

From Scenario to Prototype

Developing Prototype Hardware

These participatory design sessions confirmed our initial impression that force-feedback devices to support the sense of touch would be particularly useful in molecular modeling.

General-purpose force-feedback devices are not currently commercially available, so we had to design and build our own. Our initial force-feedback prototype, developed prior to our participatory design work, was based on Minsky’s 2-D force-feedback joystick [12]. We were also influenced by the 6-D robotic arm used by Brooks et al. for enzyme docking [2], and by the force-feedback steering wheel used in Atari’s Hard Drivin’ arcade game [16]. Since the work started we have become aware of other related devices, including Iwata’s 9-D manipulator [8] and the force-feedback versions of instrumented gloves [16].

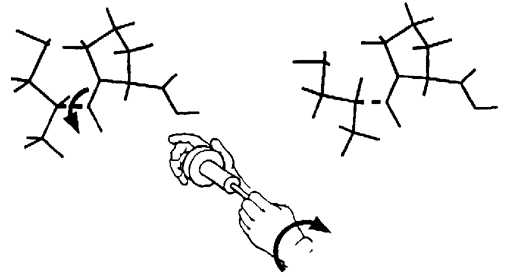

Our participatory design sessions suggested a smaller and simpler force-feedback device that would be more useful in molecular modeling applications than the 2-D joystick. This hand-held device would have one torque motor to provide torque feedback: as the participant twisted the shaft, the device could twist back as appropriate. This was directly suggested by the idea for an electronic Dreiding model for molecular modelers, where the modelers could deal with a computer model of a molecule in the same physical ways that they currently deal with physical Dreiding models of molecules.

Our portable torque-feedback device uses the same basic electronics as our version of the 2-D joystick, but much simpler mechanics. The 2-D joystick converts the output of torque motors into position offsets in the X and Y directions, whereas the torque-feedback device has no need for such conversion.

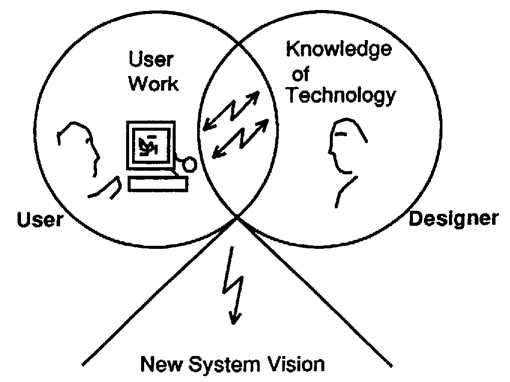

Figure 2, drawn to scale, shows the relative size and shape of our initial 2-D joystick versus the later 1-D device. The 2-D force-feedback joystick was about 28 inches tall and 20 inches square. The portable torque-feedback device was about 7½ inches tall and 2½ inches in diameter.

Figure 2: Force-Feedback Devices: Before and After Participatory Design with Chemists

Figure 2: Force-Feedback Devices: Before and After Participatory Design with Chemists

Developing Prototype Software

The scenario of electronic Dreiding models led to the development of our initial software prototype which the chemists tested a few months later in a visit to one of our laboratories. In this prototype, the participant selects the molecule to be studied, and data is read in from a text file in standard PDB (Protein Data Bank) format. The chemists provided PDB data for several small 30-60 atom molecules. The molecule was displayed in a window on the screen in a color-coded format similar to that used in the customer’s existing molecular modeling software.

After reading in the molecular data, there were several modes available: twisting the entire molecule using a 6-D magnetic sensor, moving the entire molecule using the sensor, and selecting a bond that the participant would like to rotate. All this mode selection, including the specification of the bond, was done via the keyboard. We focused our time developing the presence features within each mode, rather than on improving the usability of the control structures of the prototype.

Selecting a bond to rotate started the mode that used the torque-feedback device. As the participant rotated the molecule around the bond, the device provided feedback based on an estimate of molecular forces. This energy curve was also displayed on the screen along with the graphical display of the molecule. The torque on the device was proportional to the gradient of the energy curve, based on the rotation of the shaft of the torque-feedback device. The graphical display of the energy curve also indicated the current position on the curve. In this first prototype, the energy curves were randomly selected from three precomputed functions, so any relationship to actual molecular forces was coincidental.

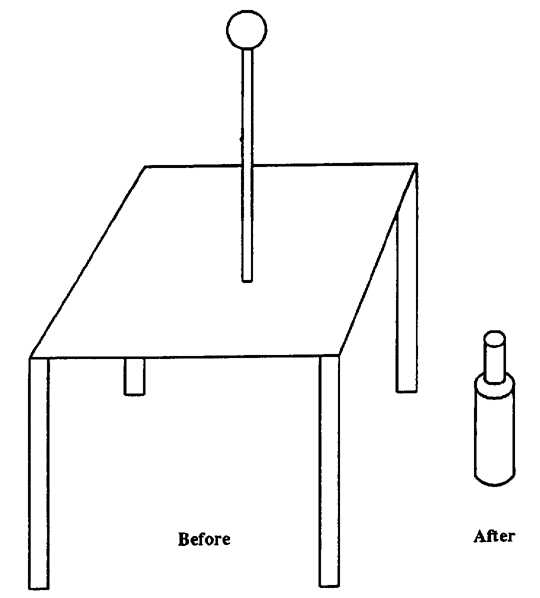

Figure 3 shows a black-and-white representation of the color display of a sample enzyme inhibitor. Moving from the conformation on the left-hand side of the figure to the conformation on the right involves two steps. First, the chemist selects the bond (indicated in Figure 3 with the thick dotted line) so that the left-hand side of the molecule would be rotated. The chemist then rotates the shaft of the torque-feedback device about 60 degrees towards him- or herself, and the left-hand side of the molecule also rotates about 60 degrees towards the chemist.

Figure 3: Rotating an Enzyme Inhibitor Around a Selected Bond

Figure 3: Rotating an Enzyme Inhibitor Around a Selected Bond

As the shaft is rotated, the chemist feels resistance to the rotation based on the gradient of a molecular energy curve. In this first prototype, this energy curve was based on random data. In a more advanced prototype, the energy gradient would be based on the varying differences in distance between the atoms in the molecule. In the example in Figure 3, this would lead to a decrease of energy at first, as the top-most atoms move further apart. At the local energy minimum, no torque output is produced. The energy would increase again towards the end of the rotation as the bottom-most atoms move closer together, leading to greater resistance or torque output.

Iterative Design Results

Despite the limitation of the arbitrary energy curves, the prototype was compelling for the chemists. The most experienced chemist noted that the prototype was “Very nice… I’m already playing… Feels great to me… This is really neat.”

Torque feedback played a different role in exploring the molecular model than the chemists had expected. The senior chemist noted that instead of using torque feedback to find good conformations (how the molecule should be twisted around different bonds), he was using the graphical display for that purpose. The torque feedback aided him in developing a physical understanding of the molecule. The combination of the graphical and force display seemed to provide a “very rapid way to examine the conformational space.”

We had told the chemists before the demonstrations began that the energy curves displayed on screen and via the torque-feedback device were randomly generated. Nevertheless, the chemists felt as if they were dealing with an approximation of the actual energy curves for the molecule. This demonstrated the power of the combined video and force display for conveying a sense of presence. It also showed that high presence can amplify the “garbage in garbage out” problems that can plague computer-based systems.

This iterative design session also uncovered two limitations with the prototype torque-feedback device itself. The first limitation was the inability to turn the torque feedback off. In one scenario, the chemist may want to choose a bond, rotate it to the desired position, then keep choosing other bonds and rotating as desired. In this scenario it is important to have a mode where the torque feedback is off, because the chemist may want to leave a bond in a relatively high-energy conformation. That could not be done if the torque feedback is pushing the chemist away from that position towards a local energy minimum. A button on the device is useful for this and other control functions.

The second limitation was the quantization of the device. In this prototype, the torque feedback was quantized in 5-degree increments of the 360 degrees of rotation. The junior chemist believed this reduced the feel of the torque-feedback unit as a high-resolution device, even though this level of quantization was the highest he had seen for computing molecular forces in existing molecular modeling computer software. We speculate that adding some interpolation, or doing unequal sampling where the energy is sampled most at the lowest levels of change (the lowest values of the first derivative) would add more presence. Despite this limitation, the chemist felt the prototype gave “a feel for the degree of fineness of the rotational space around bonds.”

Participatory design involves being prepared to discard technological ideas if new paths better meet customer needs. Customer participation includes making decisions, not simply being asked for advice. During our first iterative design session, the molecular modeling customers spent about 1 hour with prototypes involving the force-feedback devices and about 2 minutes with another prototype which used the head-mounted display. Their experience confirmed their initial hunch that force feedback met their needs while the head-mounted display did not. A revised scenario focused on supporting the senses of touch and hearing to complement screen-oriented displays.

Our participatory design sessions have not yet resulted in a finished product. Further work needs to be done to make this invention into a practical product for molecular modeling use. Iterative participatory design work has been hampered by financial cutbacks at both the pharmaceutical and computer companies. This seems a particular hazard when conducting participatory design of new technology during an economic recession.

Conclusions

When we started our participatory design work, we expected to learn new ways to apply presence technology to make it useful in different work contexts. We did not expect to invent a new presence technology device as we did here. In this case, participatory design led to the invention of a simpler device that was cheaper and easier to build than our initial prototype, while also being more useful in some work contexts.

The portable torque-feedback device adds to the repertoire of presence devices, especially those that support the sense of touch in human-computer interaction. Its portability makes it suitable for use in combination with current head-mounted display systems as well as with workstations. Because the torque feedback is presented to the hand by a grasped device rather than to the fingers via computerized clothing, a wider range of forces can be applied safely than is the case with force-feedback gloves.

Applications of the portable torque-feedback device are not limited to molecular modeling. The device can be used for other applications where torque feedback is useful. These applications could include the industrial design of the feel of knobs and dials as well as general purpose information visualization. Usability for these different applications could be enhanced by a set of “Swiss Army” style attachments to the shaft of the device, such as knobs, dials, and steering wheels.

Participatory design is an approach that responds to its context, rather than a fixed set of procedures used in all situations. Our design sessions with the chemists succeeded, even though they did not take place in the five discrete steps I had initially anticipated. Specific design activities proceeded as needed in the context of a collaborative relationship.

Our difficulties with participatory design came in initiating and sustaining the process, not in applying the process in design sessions at customer and computer company sites. Finding and enrolling appropriate customer participants for the participatory design process remains a challenge for engineers in large product development organizations. Our use of the company’s internal electronic network to find participants eventually worked, but it was slow. Sustaining a commitment to participatory design work for new technology also was a problem for us.

Developing useful, enjoyable, and appropriate technology that enhances presence for computer users is an ongoing challenge. Participatory design has steered computer engineers and chemists in some new design directions. This experience indicates that participatory design can be used to develop new computer technology as well as new computer-based application systems.

Acknowledgments

Tom Stockebrand dubbed our collaboration the Presence project and moved this project from mockups to working prototypes, among many other contributions. James Munson was co-inventor of the portable torque-feedback device. The prototypes were developed by James Munson, RuthAnn Abruzzi, John Gilstrap, Robert Clemens, Pete Pittman, and Pin Fong Ng. Figure 1 was provided by Karen Holtzblatt and Sandy Jones. Eliot Tarlin and Minette Beabes provided the design and rhetoric perspectives on presence, respectively.

Disclaimer

The views expressed in this paper are those of the author and do not necessarily reflect the views of Digital Equipment Corporation.

References

- Blomberg, J. L. and Henderson, A. Reflections on participatory design: Lessons from the Trillium experience. In Proc. CHI ’90 Human Factors in Computing Systems (Seattle, WA, April 1-5, 1990), ACM, New York, 353-359.

- Brooks, F. P., Jr., Ouh-Young, M., Batter, J. J. and Kilpatrick, P.J. Project GROPE — Haptic displays for scientific visualization. Computer Graphics, 24, 4 (August 1990), 177-185. Proc. SIGGRAPH ’90 (Dallas, TX, August 6-10, 1990).

- Ditlea, S. Another world: Inside artificial reality. PC/Computing, 2, 11 (November 1989), 90-102.

- Ehn, P. Work-Oriented Design of Computer Artifacts. Arbetslivscentrum, Stockholm, 1988. Available from Lawrence Erlbaum Associates, Hillsdale, NJ.

- Gilles, W. The presence of products: A question of perspective. Innovation, 4, 3 (1985), 5-8.

- Grudin, J. Systematic sources of suboptimal interface design in large product development organizations. Human-Computer Interaction, 6, 2 (1991), 147-196.

- Holtzblatt, K. A., Jones, S. and Good, M. Articulating the experience of transparency: An example of field research techniques. SIGCHI Bulletin, 20, 2 (October 1988), 45-47.

- Iwata, H. Artificial reality with force-feedback: Development of desktop virtual space with compact master manipulator. Computer Graphics, 24, 4 (August 1990), 165-170. Proc. SIGGRAPH ’90 (Dallas, TX, August 6-10, 1990).

- Johnson, J., Ehn, P., Grudin, J., Nardi, B., Thoresen, K. and Suchman, L. Participatory design of computer systems (panel). In Proc. CHI ’90 Human Factors in Computing Systems (Seattle, WA, April 1-5, 1990), ACM, New York, 141-144.

- Krueger, M. W. Artificial Reality II. Addison-Wesley, Reading, MA, 1991.

- Laurel, B. Computers as Theatre. Addison-Wesley, Reading, MA, 1991.

- Minsky, M., Ouh-Young, M., Steele, O., Brooks, F. P., Jr. and Behensky, M. Feeling and seeing: Issues in force display. Computer Graphics, 24, 2 (March 1990), 235-243. Proc. 1990 Symposium on Interactive 3D Graphics (Snowbird, UT, March 25-28, 1990).

- Mohamadi, F., Richards, N. G. J., Guida, W. C., Liskamp, R., Upton, M., Caufield, C., Chang, G., Hendrickson, T. and Still, W. C. MacroModel — An integrated software system for modeling organic and bioorganic molecules using molecular mechanics. Journal of Computational Chemistry, 11, 4 (April 1990), 440-467.

- Mountford, S. J., Buxton, B., Krueger, M., Laurel, B. and Vertelney, L. Drama and personality in user interface design (panel). In Proc. CHI ’89 Human Factors in Computing Systems (Austin, TX, April 3-May 4, 1989), ACM, New York, 105-108.

- Perelman, Ch. and Olbrechts-Tyteca, L. The New Rhetoric: A Treatise on Argumentation. Trans. J. Wilkinson and P. Weaver. University of Notre Dame Press, Notre Dame, IN, 1969. Original French version published in 1958.

- Rheingold, H. Virtual Reality. Summit Books, New York, 1991.

- Rorty, R. Essays on Heidegger and Others: Philosophical Papers Volume 2. Cambridge University Press, Cambridge, 1991.

- Wixon, D. and Good, M. Interface style and eclecticism: Moving beyond categorical approaches. In Proc. Human Factors Society 31st Annual Meeting (New York, October 19-23, 1987), Human Factors Society, Santa Monica, CA, Vol. 1, 571-575.

- Wixon, D., Holtzblatt, K. and Knox, S. Contextual design: An emergent view of system design. In Proc. CHI ’90 Human Factors in Computing Systems (Seattle, WA, April 1-5, 1990), ACM, New York, 329-336.

Copyright © 1992 by the Association for Computing Machinery, Inc. Permission to make digital or hard copies of part or all of this work for personal or classroom use is granted without fee provided that copies are not made or distributed for profit or commercial advantage and that copies bear this notice and the full citation on the first page. Copyrights for components of this work owned by others than ACM must be honored. Abstracting with credit is permitted. To copy otherwise, to republish, to post on servers, or to redistribute to lists, requires prior specific permission and/or a fee. Request permissions from Publications Dept, ACM Inc., fax +1 (212) 869-0481, or permissions@acm.org.

This is a digitized copy derived from an ACM copyrighted work. ACM did not prepare this copy and does not guarantee that is it an accurate copy of the author’s original work.